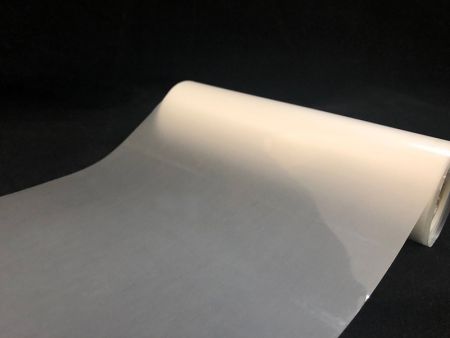

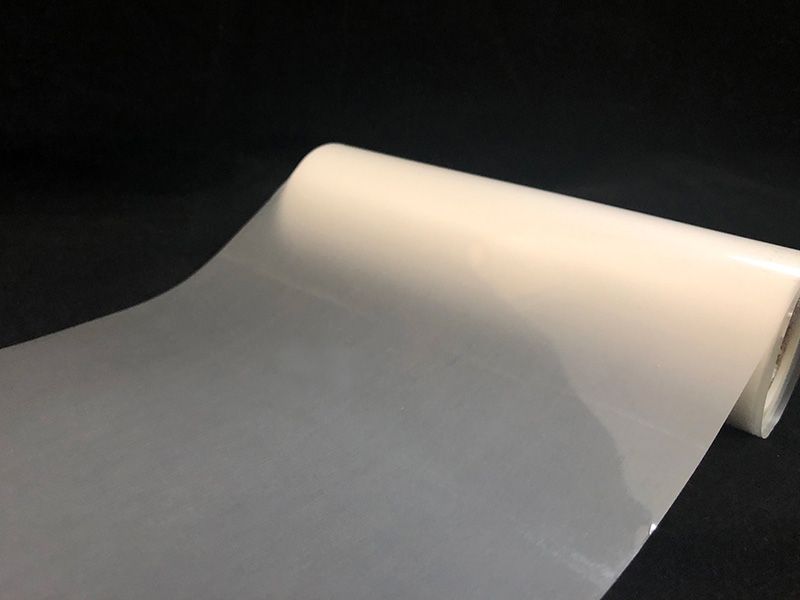

Printable Release Film

Printable release film's major features are even coating, stable release force, outstanding evenness, and won't affect the function of the laminated materials. Printable release film works like general release film and could be applied to various composite materials as functional transfer film in packaging, printing, lamination process. Suitable for printing, packaging and other industries. The release layer after hot stamping can be reprinted.

If you wish to print on the box after the packaging box underwent release film hot stamping process, this film could satisfy your needs and adds values to the products. Our products have passed strict certifications and verifications process of En71-3, CP65, REACH, RoHS, and SGS. We conduct all-round inspections to ensure safety of your products in the market.

Features

- Printable.

- Stable in release.

- Outstanding surface evenness, coated evenly.

Specification

- Applicable Materials: Paper, PVC, fabric, synthetic leather, etc.

- Color Options: Customizable according to customer requirements, catering to different design styles and application scenarios.

- Hot Stamping Temperature Range: 140°C - 200°C, suitable for diverse application processes.

- Standard Size: 640mm x 120M, or customizable based on customer needs.

Ordering Information

- Minimum Order Quantity: Depending on required specifications. (Please contact our sales representatives for confirmation).

- Lead Time: Defined productions and inspections are based on your requirements. (Please contact our sales representatives for confirmation)