Quality Control and Management

ISO Management

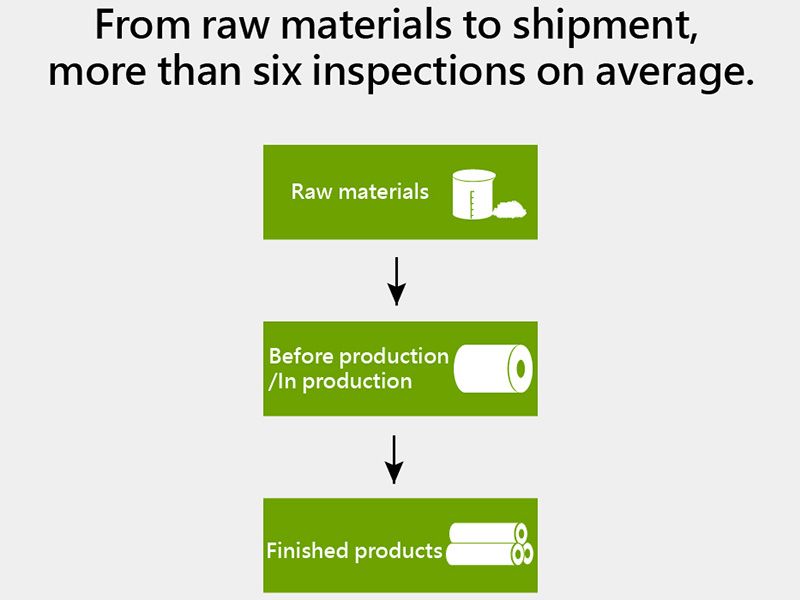

Ginkgo follows strict standard quality requirement. For that we introduce ISO management and establish intact traceability chain. We perform regular inspections and sampling inspections of each batch of products, take pictures, and keep the retention samples of the finished products. We test if our products have excellent release, adhesion, and so forth. Each test is tailored for different products. From raw materials to finished products, every procedure is under strict control and management in order to add values to your products and enhance your business competitiveness.

Component Safety:

To comply with the latest strict management regulations of chemicals, we have carried out conformity assessments to ensure our products conform to EU rules. We have passed more than one thousand toxicity tests. We guarantee you high quality and safety of our products.

Intertek's inspection proved that the product complies with the following regulations:

1. En71-3 (En71-3 : 2013 + A2 : 2017 Safety of Toys)

2. CP65 (California Proposition 65)

3. REACH- (Registration, Evaluation And Authorization Of Chemicals System)

4. RoHS- (The Restriction Of The Use Of Certain Hazardous Substances In Electrical And Electronic equipment)

5. SGS (Societe Generale de Surveillance S.A.)

Nine Test Items

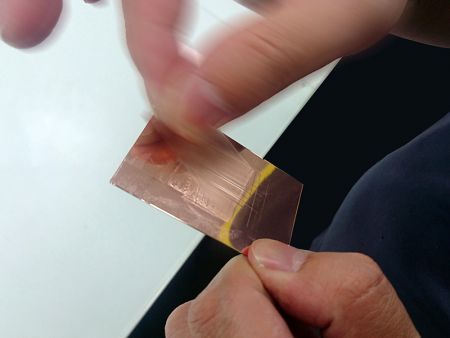

- Cross-cut Test: We use 3M-610 tape on film and remove the tape rapidly to see if it peels off with tape.

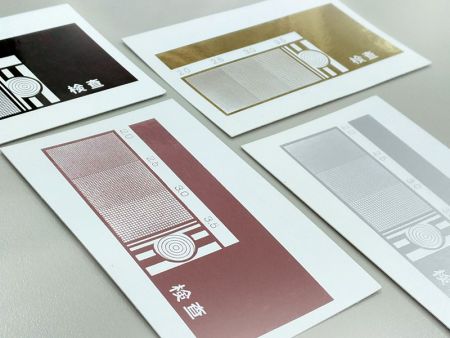

- Definition Test: To check the carrier film is fully transferred onto paper.

- Release Test: To test if foil is fully released after hot stamping.

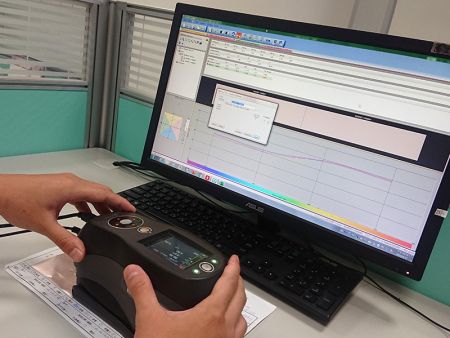

- Color Matching: Using spectrophotometer to check the color deviation.

- Temperature Test: Put in the drying oven. No visible color fading.

- Abrasion Test: Using color fastness rubbing to test the abrasion resistace.

- Alcohol Test: Soaked in alcoholic solution and the color stays unchanged.

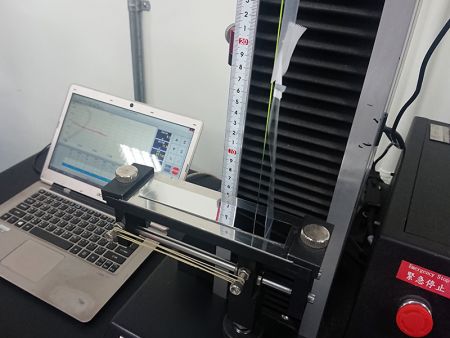

- Hardness Test: Using hardness tester to test the hardness of the foil.

- QUV Test: Using QUV tester to test the weatherability of the foil.