Release films for the electronics, optical, and printing industry

Transferable release layer for tapes, medical, touch-panel applications

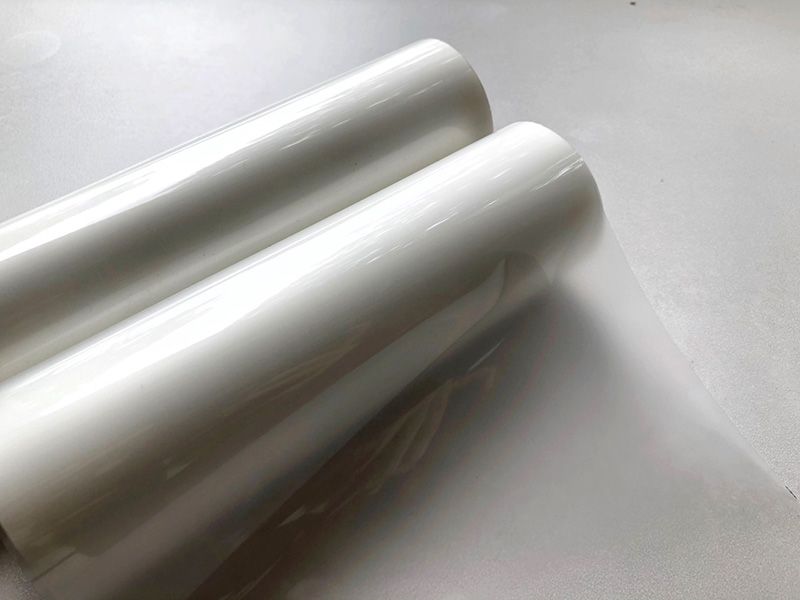

The release film is made by coating a release agent on PET polyester film, OPP film, and paper carrier; therefore, the release force of the film can separate the surface from other substrates and isolate the viscous materials.

As the stable release force for various demands, the release films are suitable for functional transfer films with multiple composite materials. Release films are widely utilized in different products and applications, including stickers, tapes, optical materials, automotive films, solar control films, and others.

Ginkgo's release films have dust-free and consistent coating layers with perfect uniformity, which significantly lowers our customers' defect rate and helps achieve higher performance. It makes our release films the foremost choice of many industries such as packaging, printing, electronics, medical, optical, and labeling.

Vision and evolution of release films

Facing rising demands for advanced applications, Ginkgo keeps enhancing the stability of release force and better transfer characteristics. All efforts are only for offering comprehensive solutions to fulfill various needs and requirements.

If you need release films for appliances and electronics, please refer to the "products" below, or click the "contact us" above and let us help you.

Sales region

Because of Ginlgo's release film's exceptional properties and stable performance, we have provided our foils over China, Europe, Japan, Taiwan, and the United States.

If you are interested in our products, please don't hesitate to contact us. Ginkgo will provide the best solution for you while delivering consistency and reliability.

Related Info

- Types of Suitable Material: According to Customer Product Requirements, Provide Material Suggestions

- Working Process: Provide applicable processes according to customer product requirements

- Related Products

Hard Coating Film

Hard coating technology uses UV coating materials to replace general coating materials. By hot transferring UV coating materials onto the substrates to be protected which increase the hardness to 2H level. It is mainly applied to products having a plastic surface such as PC, PMMA and ABS. After using our hard coating films, not only increases the hardness and scratch-resistance, but also optimizes the post-processing feature with great adhesion property. Product specification and hardness could be adjusted based on our client's needs, it could be applied to interior decoration, panels, smart phones for external strengthening and abrasion resistance purposes.

Lamination Film

Lamination film could be fully attached to various substrates such as plastic and paper, allowing them to exhibit gloss. The difference between hot stamping foil and lamination film is the PET film layer is kept after the laminating process, leaving an extra protection to the surface of the products, keep moisture and oxygen away. It could work as a protective film. It also has better abrasion resistance and scratch resistance than general hot stamping foil, and have great adhesion to various substrates such as labels, greeting cards, wine bottles, packaging paper boxes, lampshades, etc.

Release Film

Release film is coating with release agents on PET film would allow the surface to detach from other substances and avoid viscous materials. It is evenly coated, intact surface and high transparency. Could be applied to various composite materials as functional transfer, or used for transfer and release. It applied to electronics industry, printing industry and so forth.

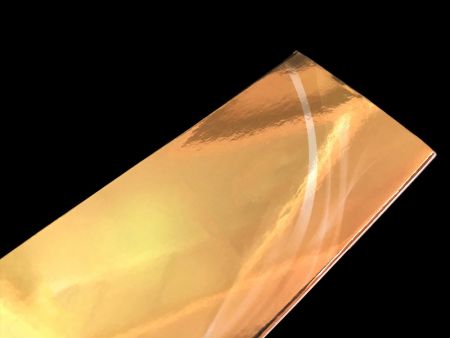

Plastic Packaging Hot Stamping Foil

Hot stamping foil for plastic packaging has high chemical resistance and good adhesion to various plastic materials so the trademark or logo of the products won't come off. Suitable for industries such as cosmetics product packaging materials, household appliances and so forth.