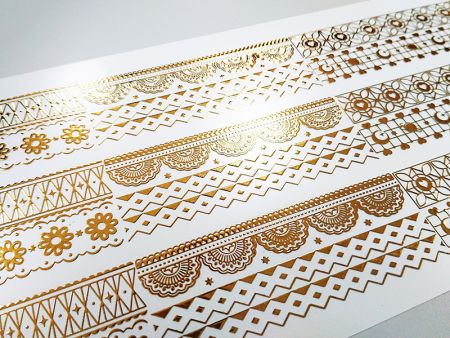

Cold foils for the printing industry

Suitable for narrow-web flexographic and sheet-fed offset printings

Cold foils can be applied to the surface using a cold foil module on a web-fed or sheet-fed printing press. The cold foil is adhered to a substrate first and then over-printed by the press's CMYK stations, resulting in any color in metallic finishes. The cold foil is attached to UV or regular inks in a high-speed process that eliminates the need for a stamping die.

Cold foils give a brilliant metallic effect and achieve the purpose of adding value to the products. It is commonly utilized in alcohol labels, cigarette boxes, packaging box printings, cosmetic packaging, and other products.

Furthermore, the cold foils are suitable for various materials such as PP, PE, TPU, and paper. As a result, the cold foils are ideal for label, printing, packaging, and paper industries that require high-speed mass and cost-effective production.

Ginkgo can provide an extensive range of cold foil colors, providing customers with countless creative ideas and making their product packaging more distinctive.

Vision and evolution of cold foils

Ginkgo is constantly improving the formulation of cold foils, making them more competitive and easier to apply. We are not only offering the choice of cold foils but also the inspirations and elements of design for your packaging.

If you need cold foils, please refer to the "products" below, or click the "contact us" above and let us help you.

Sales region

Due to the exceptional quality and consistent performance, Ginkgo has provided cold foils over China, Europe, India, Korea, Taiwan, and the United States.

If you are interested in our products, please don't hesitate to contact us. Ginkgo will provide the best solution for you while delivering consistency and reliability.

Related Info

- Types of Suitable Material: Paper

- Working Process: Cold Stamping

- Related Products

Rainbow Metallic Film

Certified High-End Packaging Solution for Luxury and Fashion Industries

Rainbow Metallic Film is a decorative hot stamping foil material that has passed rigorous international certifications, including En71-3, CP65, REACH, RoHS, and SGS, ensuring the product's environmental friendliness and safety. We conduct comprehensive quality inspections to ensure that your product performs optimally in the market, meeting the demands of the high-end sector.Rainbow Metallic Film is widely used in fashion apparel decoration and cosmetics packaging. It utilizes advanced coating technology to give products a unique rainbow sheen, enhancing their aesthetic appeal. Whether for brands with special design requirements or companies looking to highlight a premium feel, Rainbow Metallic Film is the ideal choice.

Translucent Foil

Translucent foil has differ production process from the general hot stamping foil, which could perform different effects, by applying translucent foil onto the printed colors will create thousauds of combinations with special layering effects. Many cosmetics related industries and designers are using our translucent foils in packaging designs and creating the unique style. Our translucent foils have passed strict certifications and verifications process of En71-3, CP65, REACH, RoHS, and SGS. We conduct all-round inspections to ensure safety of your products in the market.

Holographic Foil

Holographic foil requires excellent hologram embossing technology to display a special appearance and catch customers' attention. The foil is often used in hot stamping on various papers and plastic materials and facilitate decorative functions. It could be applied to cosmetics, paper box, lure bait, credit card, passport, and anti-counterfeit label, it is flexible and available for satisfying different, customized layouts, colors, and patterns.

Digital Foil

Digital foil is digital printing with metallic touch. Injecting UV varnish on substrates such as general paper, printing paper, OPP lamination material, and polyethylene terephthalate material. Processed through UV hardened system and hot stamping. Metallic shine transferred onto UV varnish brings out the glossy effects on products and shows the finest details.