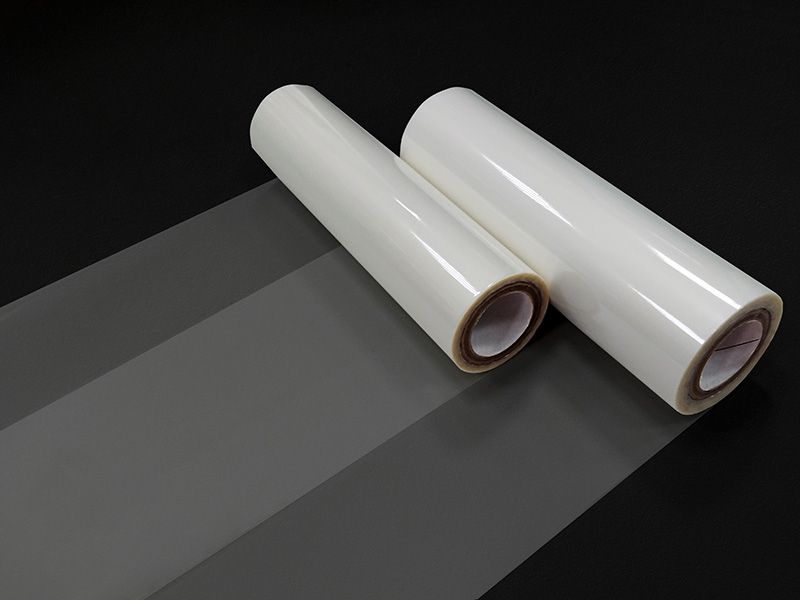

Hard Coating Film

Hard coating technology uses UV coating materials to replace general coating materials. By hot transferring UV coating materials onto the substrates to be protected which increase the hardness to 2H level. It is mainly applied to products having a plastic surface such as PC, PMMA and ABS. After using our hard coating films, not only increases the hardness and scratch-resistance, but also optimizes the post-processing feature with great adhesion property. Product specification and hardness could be adjusted based on our client's needs, it could be applied to interior decoration, panels, smart phones for external strengthening and abrasion resistance purposes.

The structure of hard coating film could be classified into two categories: hot transfer and printing, please refer to below figures for descriptions. Our products have passed strict certifications and verifications process of En71-3, CP65, REACH, RoHS, and SGS. We conduct all-round inspections to ensure safety of your products in the market.

Application Guidelines

1. Forming Hard Coating Film

Available for thermoforming, high ductility.

Hardness: H (Different hardness per substrate)

2. Non-forming Hard Coating Film

Suitable for smooth surface texture.

Hardness: 2H (Different hardness per substrate)

Features

- High abrasion and scratch resistance.

- External reinforcement of products.

Specification

- Applicable Materials: Paper, PVC, fabric, synthetic leather, etc.

- Color Options: Customizable according to customer requirements, catering to different design styles and application scenarios.

- Hot Stamping Temperature Range: 140°C - 200°C, suitable for diverse application processes.

- Standard Size: 640mm x 120M, or customizable based on customer needs.

Structure for General Hot Transfer

Ordering Information

- Minimum Order Quantity: Depending on required specifications. (Please contact our sales representatives for confirmation).

- Lead Time: Defined productions and inspections are based on your requirements. (Please contact our sales representatives for confirmation)